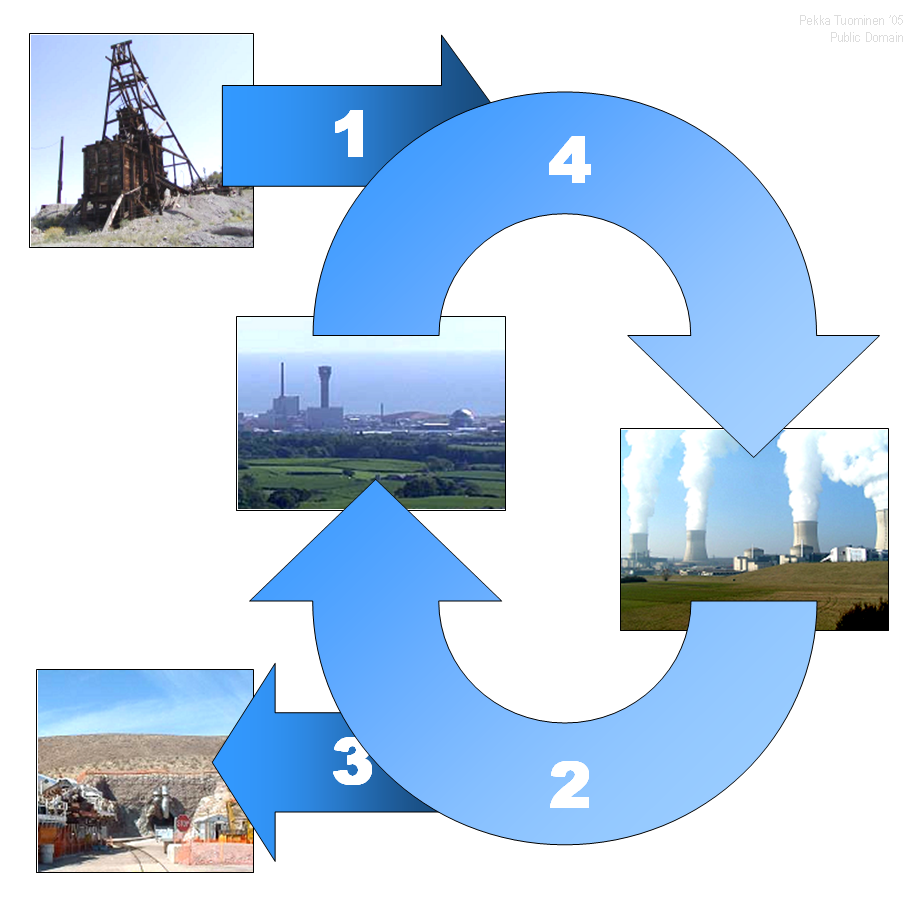

Nuclear fuel is a material that can be consumed in order to produce nuclear energy, whereas fossil fuel is burned for energy. Nuclear fuel in a nuclear fuel cycle can refer to the fuel itself or to physical objects such as fuel rods which contain the nuclear material and other materials designed for neutron moderating or neutron reflecting. The nuclear fuel cycle, also known as the nuclear fuel chain, is a series of steps describing the "life" of the nuclear fuel. It is basically composed of the front end, during which the nuclear material is processed; steps during the service period in which the nuclear fuel powers reactors in order to produce energy; and steps during the back end in which necessary operations are required in order to manage, contain and either reprocess or dispose of spent nuclear fuel. There has been much debate weather which of the steps of the back end is more economic and most of all, environmentally friendly. An open fuel cycle is when the spent nuclear fuel is not reprocessed and a closed fuel cycle is when it is reprocessed. Below is a diagram that shows the cycle more briefly.

PWR Fuel

Pressurized water reactor (PWR) fuel consists of cylindrical rods put into bundles. A uranium oxide ceramic is formed into pellets and inserted into Zircaloy tubes that are bundled together. The Zircaloy tubes are about 1 cm in diameter, and the fuel cladding gap is filled with helium gas to improve the conduction of heat from the fuel to the cladding. There are about 179-264 fuel rods per fuel bundle and about 121 to 193 fuel bundles are loaded into a reactor core. Generally, the fuel bundles consist of fuel rods bundled 14x14 to 17x17. PWR fuel bundles are about 4 meters in length. In PWR fuel bundles, control rods are inserted through the top directly into the fuel bundle. The fuel bundles usually are enriched several percent in 235U. The uranium oxide is dried before inserting into the tubes to try to eliminate moisture in the ceramic fuel that can lead to corrosion and hydrogen embrittlement. The Zircaloy tubes are pressurized with helium to try to minimize pellet-cladding interaction which can lead to fuel rod failure over long periods.

BWR Fuel

In boiling water reactors (BWR), the fuel is similar to PWR fuel except that the bundles are "canned"; that is, there is a thin tube surrounding each bundle. This is primarily done to prevent local density variations from affecting neutronics and thermal hydraulics of the reactor core. In modern BWR fuel bundles, there are either 91, 92, or 96 fuel rods per assembly depending on the manufacturer. A range between 368 assemblies for the smallest and 800 assemblies for the largest U.S. BWR forms the reactor core. Each BWR fuel rod is back filled with helium to a pressure of about three atmospheres (300 kPa).

CANDU Fuel

CANDU fuel bundles are about a half meter in length and 10 cm in diameter. They consist of sintered (UO2) pellets in zirconium alloy tubes, welded to zirconium alloy end plates. Each bundle is roughly 20 kg, and a typical core loading is on the order of 4500-6500 bundles, depending on the design. Modern types typically have 37 identical fuel pins radially arranged about the long axis of the bundle, but in the past several different configurations and numbers of pins have been used. The CANFLEX bundle has 43 fuel elements, with two element sizes. It is also about 10 cm (4 inches) in diameter, 0.5 m (20 in) long and weighs about 20 kg (44 lb) and replaces the 37-pin standard bundle. It has been designed specifically to increase fuel performance by utilizing two different pin diameters. Current CANDU designs do not need enriched uranium to achieve criticality (due to their more efficient heavy water moderator), however, some newer concepts call for low enrichment to help reduce the size of the reactors.

Niciun comentariu:

Trimiteți un comentariu